Acquisition lays groundwork for a breakthrough: Microchips placement as part of additively manufactured electronics solution

Sunrise, Florida, Nov. 03, 2021 (GLOBE NEWSWIRE) -- Nano Dimension Ltd. (Nasdaq: NNDM), an industry leader in Additively Manufactured Electronics (AME) / 3D-Printed Electronics (PE), and Micro Additive Manufacturing (Micro-AM), announced today that it has signed and closed a definitive agreement to acquire Essemtec AG (“ESSEMTEC”, https://essemtec.com/en/) based in Lucerne Canton, Switzerland.

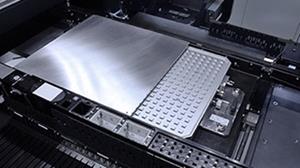

ESSEMTEC’s product portfolio is comprised of production equipment for placing and assembling electronic components on printed circuit boards (PCBs). They are a leader in adaptive highly flexible surface mount technology (SMT) pick-and-place equipment, sophisticated dispenser suitable for both high-speed and micro-dispensing, and intelligent production material storage and logistic system. Its products are equipped with a sophisticated software package which makes extensive and efficient material management possible.

ESSEMTEC’s equipment and software have been having impact with customers since their first machine was introduced. As their high-tech solution can be adjusted quickly and easily to meet wide ranging requirements, they are able to respond to all manner of customer needs, particularly in high-mix-low-volume production environment. Their portfolio of products will continue to be available to the thousands of organizations that have called themselves a customer of ESSEMTEC, while also being part of the AME revolution that Nano Dimension is driving with its existing technology.

ESSEMTEC financial highlights:

- 12 months ended 12/31/2020 revenue was $17.2 million; gross margin was 60%

- 8 months ended in 08/31/2021 revenue was $15.4 million; gross margin was 60%

- Backlog (signed purchase orders) as of 09/17/2021 was approximately $6.9 million

Transaction outline:

- Nano Dimension will pay ESSEMTEC shareholders a total sum, in cash, ranging between $15.1 million to $24.8 million

- $15.1 million will be paid upon closing

- An additional amount of up to $9.7 million will be paid over 14 months based on a pre-agreed performance-based formulas.

| https://www.youtube.com/essemtec | ESSEMTEC video assortment. |

| https://vimeo.com/639289488 | ESSEMTEC company video presentation |

| https://vimeo.com/596456503 | ESSEMTEC Invitation Productronica 2021 |

| https://vimeo.com/478592222 | ESSEMTEC Video about solution with comments |

Franz-Xaver Strueby, Chief Executive Officer of ESSEMTEC, commented, “It is an exciting combination of two leading technology leaders serving the PCB and wider electronic industry segments. The combination of Nano Dimension’s strength in the Americas with ESSEMTEC’s strong presence in Europe will enhance both product lines. Additionally, I believe that the merger of the technologies will yield enormous influence and transformational momentum in the world of 3D printed electronics and assembly. The ESSEMTEC team, as well as me personally, are looking forward to continuing our journey as part of the combined teams of ESSEMTEC and Nano Dimension.”

Yoav Stern, Chairman and Chief Executive Officer of Nano Dimension, shared, “ESSEMTEC’s scientists and engineers and other team members, all of whom joined Nano Dimension upon closing of this transaction, are leading experts and industry veterans in machine building, software, mechanical automation, and robotics. They are going to continue to be led by their present management crew, supported by Ziki Peled, COO of Nano Dimension.”

Mr. Stern added, “ESSEMTEC’s present products fit Nano Dimension’s PCB and PCB assembly markets, as well as the Original Equipment Manufacturers (OEM) verticals which we serve. As such, we hope to leverage the distribution channels and go-to-market efforts of both organizations. In parallel, our mutual vision is to merge the technologies of our micro-electronic 3D-fabrication machines for Hi-PEDs® (Hi-Performance Electronic Devices) with ESSEMTEC’s fuller suite of in-fabrication-process-equipment-assembly capabilities.”

“No less important”, Mr. Stern said, “is our intention to use our newly acquired deep learning based artificial intelligence technologies from our DeepCube acquisition to become the “robotic brains” for ESSEMTEC systems. We expect this will improve yield and throughput and drive a more seamless integration with Nano Dimension’s AME systems. ESSEMTEC’s machines fit the larger picture of Nano Dimension’s vision, aiming to establish “INDUSTRY 4.0” solutions, which entail building an artificial intelligence “distributed digital manufacturing application” rather than just machines as capital equipment. The end goal is to reach a capability for maintaining an inventory of high-end PCB devices, micro-mechanical parts and Hi-PEDs® in digital form: print and assemble them as you need them, where you need them, only the quantity you need, in the best quality at competitive prices, as it is done in highest yield and throughput possible for that point in time, specifically in high mix/low volume scenarios.”

Sullivan & Worcester Tel Aviv and CMS Switzerland acted as legal counsel to Nano Dimension in connection with the acquisition.

INVESTORS CONFERENCE CALL:

November 8, 2021, at 9:00 AM ET

Nano Dimension will host an investor call to update on the above acquisition, on November 8, 2021, at 9:00 a.m. ET. To attend the conference call, please dial one of the following teleconferencing numbers. Please begin by placing your call five minutes before the conference call commences. If you are unable to connect using the toll-free number, please try the international dial-in number.

U.S. Dial-in Number: 1-866-744-5399

Israel Dial-in Number: 972-3-9180692

At: 9:00 a.m. Eastern Time, 6:00 a.m. Pacific Time

Participants can register for the conference call by navigating to

https://Veidan.activetrail.biz/nanodimension-2021.

A REPLAY will be available after the end of the conference call on the Nano Dimension website.

About ESSEMTEC

ESSEMTEC AG is a company with its development and production site in Switzerland. Its product portfolio is comprised of production equipment for electronic assembly and more. ESSEMTEC’s technology solutions can be adjusted quickly and easily to meet wide ranging requirements. ESSEMTEC’s core business is adaptive highly flexible SMT pick-and-place equipment, elaborate materials’ dispenser suitable for both high speed dispensing and micro dispensing as well as an intelligent production material storage and logistic system.

All ESSEMTEC’s products are equipped with a sophisticated software package. This software makes an extensive and efficient material management possible. Beyond that it establishes a level of user friendliness and creative leeway in the mounting and dispense design that is unique in the market. ESSEMTEC’s solutions are installed on five continents and in many different environments.

About Nano Dimension

Nano Dimension’s (Nasdaq: NNDM) vision is to transform the electronics and similar additive manufacturing sectors into an environmentally friendly & economically efficient additive manufacturing Industry 4.0 solution, while enabling a one-production-step-conversion of digital designs into functioning devices - on demand, anytime, anywhere.

Nano Dimension plans to execute on this vision by building an ecofriendly and intelligent distributed network of additively manufacturing self-learning & self-improving systems, which are designed to deliver a superior ROI to their owners as well as to Nano Dimension shareholders and stakeholders.

The DragonFly LDM® 3D printing systems serve cross-industry High Performance Electronic Devices (Hi-PEDs®) fabrication needs, by depositing proprietary conductive and dielectric materials simultaneously, while concurrently integrating in-situ capacitors, antennas, coils, transformers, and electromechanical components. The outcomes are Hi-PEDs® which are integral enablers of autonomous intelligent drones, cars, satellites, smartphones, and in vivo medical devices. These products enable iterative development, IP safety, fast time-to-market, and device performance gains. With DragonFly LDM®, a revolution happens at the click of a button, allowing customers to go from CAD to a functional device in a matter of hours instead of weeks; creating products with better performance; reducing the size and weight of electronic parts and devices; enabling innovation; and, critically important, protecting IP, all the while limiting environmental pollution and chemical waste.

Nano Dimension’s Fabrica 2.0 micro additive manufacturing system enables the production of microparts based on a Digital Light Processor (DLP) engine that achieves repeatable micron levels resolution. The Fabrica 2.0 is engineered with a patented array of sensors that allows a closed feedback loop, using proprietary materials to achieve very high accuracy while remaining a cost-effective mass-manufacturing solution. It is used in the areas of micron level resolution of medical devices, micro-optics, semi-conductors, micro-electronics, micro-electro-mechanical systems (MEMS), micro fluidics and life sciences instruments.

For more information, please visit www.nano-di.com.

Forward Looking Statements

This press release contains forward-looking statements within the meaning of the “safe harbor” provisions of the Private Securities Litigation Reform Act of 1995 and other Federal securities laws. Words such as “expects,” “anticipates,” “intends,” “plans,” “believes,” “seeks,” “estimates” and similar expressions or variations of such words are intended to identify forward-looking statements. For example, Nano Dimension is using forward-looking statements in this press release when it discusses the potential benefits to Nano Dimension of the acquisition of Essemtec, the potential benefits of ESSEMTEC’s products and their ability to enhance Nano Dimension’s products, the potential for additional payments to ESSEMTEC’s shareholders, the ability of the merger of Nano Dimension’s and ESSEMTEC’s technologies to yield influence and momentum in the world of 3D printed electronics and assembly, the expectation that ESSEMTEC’s scientists and engineers and other team members will join Nano Dimension, the ability to leverage the distribution channels and go-to-market efforts of both organizations, the vision to merge the technologies of Nano Dimension’s micro-electronic 3D-fabrication machines for Hi-PEDs® with ESSEMTEC’s fuller suite of in-fabrication-process-equipment-assembly capabilities, the intention to use Nano Dimension’s deep learning based artificial intelligence technologies to become the “robotic brains” for Essemtec systems and the expectation that this will improve yield and throughput and drive a more seamless integration with Nano Dimension’s AME systems. Because such statements deal with future events and are based on Nano Dimension's current expectations, they are subject to various risks and uncertainties. Actual results, performance or achievements of Nano Dimension could differ materially from those described in or implied by the statements in this press release. The forward-looking statements contained or implied in this press release are subject to other risks and uncertainties, including those discussed under the heading “Risk Factors” in Nano Dimension’s annual report on Form 20-F filed with the Securities and Exchange Commission (“SEC”) on March 11, 2021, and in any subsequent filings with the SEC. Except as otherwise required by law, Nano Dimension undertakes no obligation to publicly release any revisions to these forward-looking statements to reflect events or circumstances after the date hereof or to reflect the occurrence of unanticipated events. References and links to websites have been provided as a convenience, and the information contained on such websites is not incorporated by reference into this press release. Nano Dimension is not responsible for the contents of third-party websites.

NANO DIMENSION INVESTOR RELATIONS CONTACT

Yael Sandler, CFO | ir@nano-di.com

U.S. Investor Relations:

Dave Gentry

RedChip Companies Inc.

Dave@redchip.com

407-491-4498 or 1-800-RED-CHIP (733-2447)

Attachments

- Fully Integrated Line Solutions and Highly Flexible Cell Solutions

- Cell Solution and Line Solution

- pic3

- pic4

- pic5