Proprietary Layered Powder Metallurgy (LPM™) Technology from Stratasys® Aimed at Delivering Cost-Effective, Production-Grade Metal Parts for Low-to-Mid Volumes

LPM Additive process revealed here. View the video now

MINNEAPOLIS & REHOVOT, Israel — (BUSINESS WIRE) — November 13, 2018 — Helping customers pioneer a new era in additive manufacturing for production-grade metal parts, Stratasys (Nasdaq: SSYS) is releasing further details of its new platform currently being developed and designed for short-run metal applications. First unveiled earlier this year, the additive platform is based on Stratasys’ innovative, first-of-its-kind “Layered Powder Metallurgy” (LPM™) technology, designed to make production of metal parts quicker, easier and more cost-effective than ever before.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20181113005581/en/

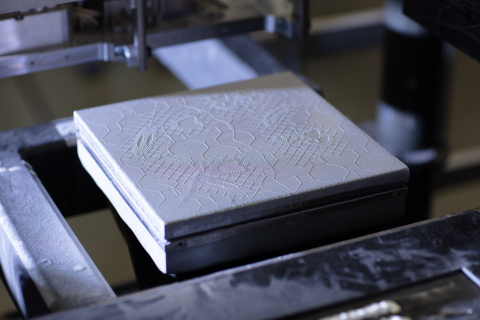

Stratasys' advanced metals platform combines the power of additive manufacturing with short-run metals parts production. (Photo: Business Wire)

Intended to disrupt conventional manufacturing approaches, the advanced platform is being developed to combine the value of additive manufacturing with short-run metal parts production. The innovative technology is built to drive improved efficiency and cost savings using standard Powder Metallurgy (PM) alloys, mechanical properties with high accuracy and controlled shrinkage, as well as extremely fast throughput.

“We note that current approaches to 3D printing metal parts leave a lot to be desired – including slow post-processing, painstakingly intricate support removal, and hours of matching and grinding. Combined with the high cost of AM powders, this means each part is expensive, with a total cost of ownership that is too hard to justify,” said Rafie Grinvald, Director of Product Marketing and Management, Stratasys. “Our new platform is being designed to transform the current metals additive manufacturing landscape – presenting a viable alternative to typical production methods – and helping customers dramatically reduce the costs of creating reliable, consistent production-grade, metal parts for short-run applications.”

Developed internally over the past several years, Stratasys’ platform incorporates the company’s proprietary jetting technology and commonly-used powder metallurgy, starting with offering Aluminium powders. The LPM™ solution includes a 3-step, additive manufacturing process combining traditional powder metallurgy with Stratasys’ PolyJet™ robust ink-jet technology. The process includes printing of boundaries with proprietary thermal ink, powder dispensing and spreading, and then compaction of the powder layer to achieve high-density and controllable shrinkage.

The end result is intended to be economically competitive vis-�nbsp;-vis cost-per-part and throughput with easy to implement post-processing and extremely high part quality. The system aims to directly address needs of customers who require production of pilot-series parts, small-batch manufacturing during product ramp-up and end-of-life, as well as customized, lightweight, complex parts. The offering is ideal for such markets as automotive, aerospace and defense.

Stratasys is currently in closed-loop feedback discussions with OEMs and Tier-1s on the new metals platform. More details – including product specs and detailed launch timelines – will be made available soon. See Stratasys in action at formnext 2018.

View the LPM additive process in action by clicking here.

Visit Stratasys at formnext 2018

Stratasys is discussing its

new metals solution and demonstrating production parts at formnext 2018

in Messe Frankfurt, Germany on Tuesday, November 13 – Friday, November

16. The company is offering exclusive hands-on demos, detailed customer

use-cases and presentations throughout the show in Hall 3.1, Stand G40.

Stratasys® is a global leader in additive manufacturing / 3D printing technology, and is the manufacturer of FDM® and PolyJet™ 3D Printers. The company’s technologies are used to create prototypes, manufacturing tools and production parts for industries, including aerospace, automotive, healthcare, consumer products and education. For 30 years, Stratasys products have helped manufacturers reduce product-development time, cost and time-to-market, as well as reduce or eliminate tooling costs and improve product quality. The Stratasys 3D printing ecosystem of solutions and expertise includes: 3D printers, materials, software, expert services and on-demand parts production. Online at: www.stratasys.com, http://blog.stratasys.com and LinkedIn.

Stratasys is a registered trademark and the Stratasys signet is a trademark of Stratasys Ltd. and/or its subsidiaries or affiliates. All other trademarks are the property of their respective owners.

Note Regarding Forward-Looking Statements

The statements in this press release relating to Stratasys’ beliefs

regarding the development process and benefits customers will experience

from the new Stratasys metal platform and Stratasys’ expectation as to

the timing of development and launch times of the new Stratasys metal

platform, are forward-looking statements reflecting management's current

expectations and beliefs. These forward-looking statements are based on

current information that is, by its nature, subject to rapid and even

abrupt change. Due to risks and uncertainties associated with Stratasys'

business, actual results could differ materially from those projected or

implied by these forward-looking statements. These risks and

uncertainties include, but are not limited to: the risk that customers

will not perceive the benefits of the new Stratasys metal platform to be

the same as Stratasys does and the risk that unforeseen technical and

development difficulties will delay the completion of development and

shipping of the new Stratasys metal platform; and other risk factors set

forth under the caption “Risk Factors” in Stratasys' most recent Annual

Report on Form 20-F, filed with the Securities and Exchange Commission

(SEC) on February 28, 2018. Stratasys is under no obligation (and

expressly disclaims any obligation) to update or alter its

forward-looking statements, whether as a result of new information,

future events or otherwise, except as otherwise required by the rules

and regulations of the SEC.